In a mechanical eccentric press the ram is driven by gears that generate a sinusoidal curve, whose approaching curve to the BDC and return stroke are symmetrical.

The stroke of ram in a mechanical eccentric press can be fixed or variable.

There are different types of kinematics in the mechanical presses besides the conventional eccentric one, each with different ram motion curve: knuckle-joint, esadrive (modified knuckle-joint), link-drive.The driving system in a mechanical press includes:

- The brake-and clutch unit

- The flywheel

- The eccentric gears

- The articulated connecting rods for the slow motion of ram.

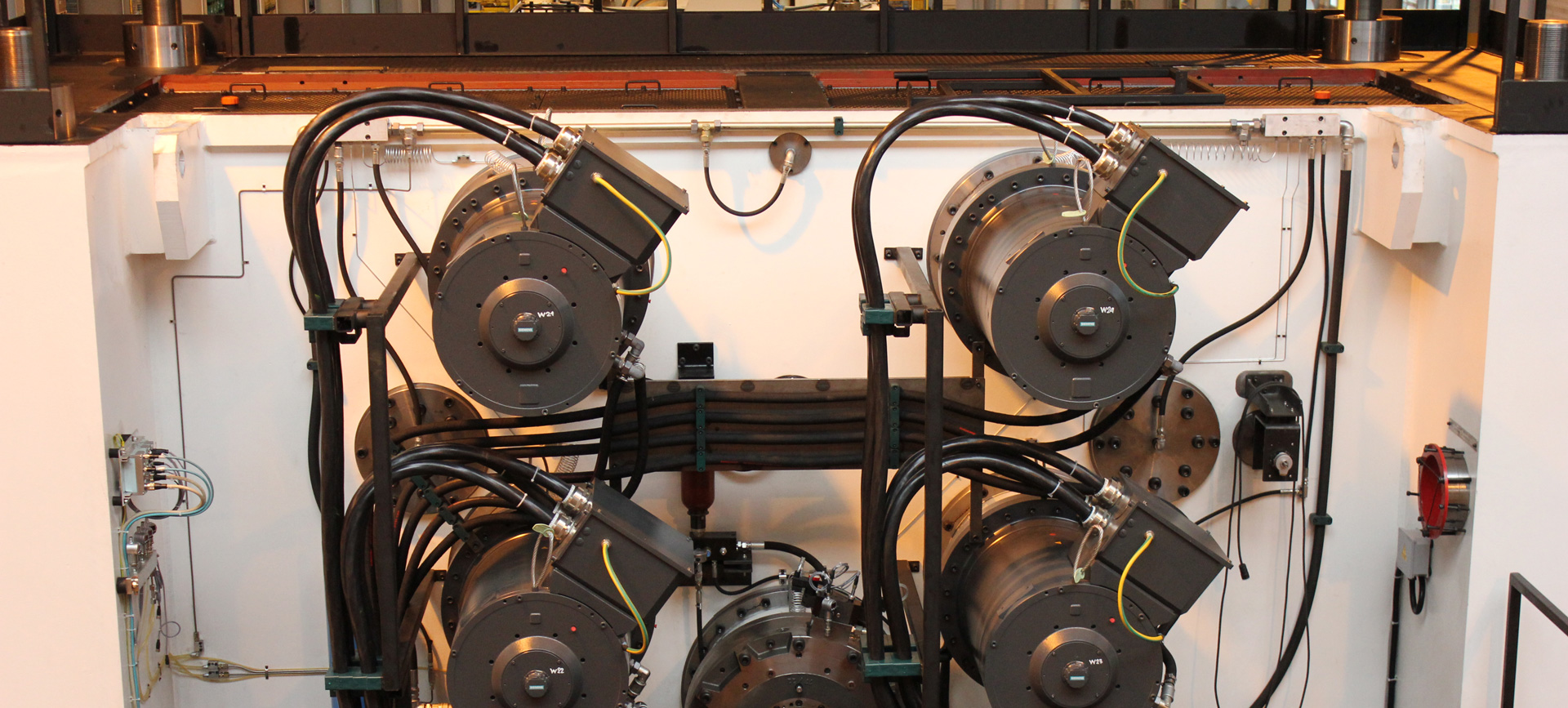

In a Balconi Servopress some mechanical components of the driving system are replaced by one or more high torque servomotors:

- The flywheel

- The clutch unit

- The main motor

In a Servopress the driving system is simpler, it has less mechanical components and the machine flexibility increases considerably:

- The press force is generated by the Servomotors

- The ram curve and speed are determined by the Servomotors speed

In such a way it is possible to obtain in all working cycle:

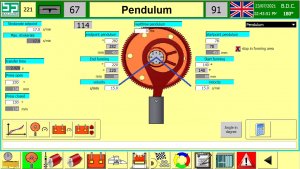

– an unlimited number of variable and programmable stroke lengths of ram

– ram curve and slow-motion speed (approaching, working, return and stop at BDC) are programmable

– it is possible to adapt the best curve, stroke length and production speed to each tool and production method.

Moreover, in the BALCONI Servopresses, it is possible to program with the Multipoint function 10 different speeds or stops inside the same curve, to make special profiles and to better form material, even when using high tensile steel.

Capacitor modules and kinetic energy management system by inertia motor for electric energy storage make energy available whenever it is required during production cycle and this avoids increasing of electric consumption, although the Servomotor power installed is very high.

The press user must not increase his factory electric supply to use a Balconi Servopress.

Compared to other similar machines existing on the market, Balconi Servopresses offer several advantages:

- Usually in the conventional mechanical presses energy is not fully available at minimum speed, whilst on other Servopresses existing on the market, full energy is not always available at maximum speed. In the Balconi Servopress full energy is always available: at minimum and as well as at maximum speed.

- Servomotors and drivers are provided with a water cooling system. This allows to achieve higher performances and it eliminates the risk of contaminating the Servomotors and the electric cubicles by dusts and oil emulsions existing in the production sites and that would require making a constant cleaning and maintenance of Servomotors and cubicles and may reduce life of electronic components.

- The water cooling system also allows to reduce the sizes of the press electric cubicles, under the same conditions of power.

- Tool set up is easier and quicker, without risk of burning the clutch and full press energy is available starting from 3 strokes per minute.

- A Balconi Servopress is supplied with ready-to-use function modules, easy to use, to choose the best working curve and to reduce set up times

- It is possible to increase production speed and productivity, to improve quality of the parts produced and to increase tool life by using the most appropriate curve.

- It is possible to reduce production costs thanks to the highest flexibility of use.

- The Balconi Servopress software gives the operator the possibility to develop his own specific running modules in complete autonomy.

Balconi Servopresses are available in the range up to 25000 kN, in several versions with one, two or four connecting rods.