In the production with transfer tools, the part to be stamped is moved into the different tool stations by means of a transfer system.

The use of a transfer tool allows to optimize material consumption.

The blank to be stamped can be fed into the press by a destacker or from an outside blanking station usually placed outside the press uprights, with a shear in the feeding line or in the first station of the tool.

Balconi transfer presses include a wide range of models to meet the most different and specific production requirements:

- Balconi manufactures transfer presses with a force from 1.000 kN up to 30.000 kN force

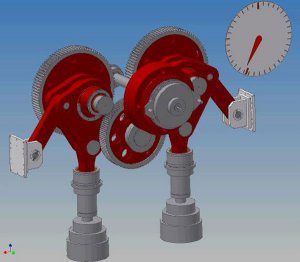

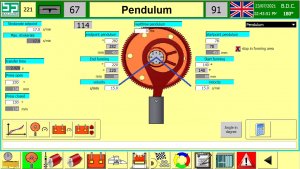

- Ram slow motion can be link-drive or Servodrive, on the ground of the different applications and of the parts to be produced.

- On the ground of the table size and of the production needs, transfer presses can be made with two or four connecting rods.

- Transfer presses usually have a large opening between the uprights to have the necessary space for the transfer system.

- Balconi transfer presses can be equipped and supplied with feeding systems or destackers, pneumatic or hydraulic blank-holders and cushions, ejectors in the ram to facilitate the part ejection from the tool station.

- Two or three axis electronic transfer systems can be provided.

- All presses can be equipped with a quick tool change system to reduce production change and set up times.

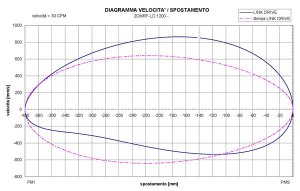

LINK-DRIVE:

This system is suitable for long stroke lengths for the production of deep drawn parts. Ram motion is slowed down during all the drawing operation with a constant speed, to optimize metal forming

SERVODRIVE:

This type of ram slow motion is made by torque Servomotors and it gives the maximum production flexibility and productivity. You can find the information concerning this type of presses in the dedicated area: “SERVOPRESSES”