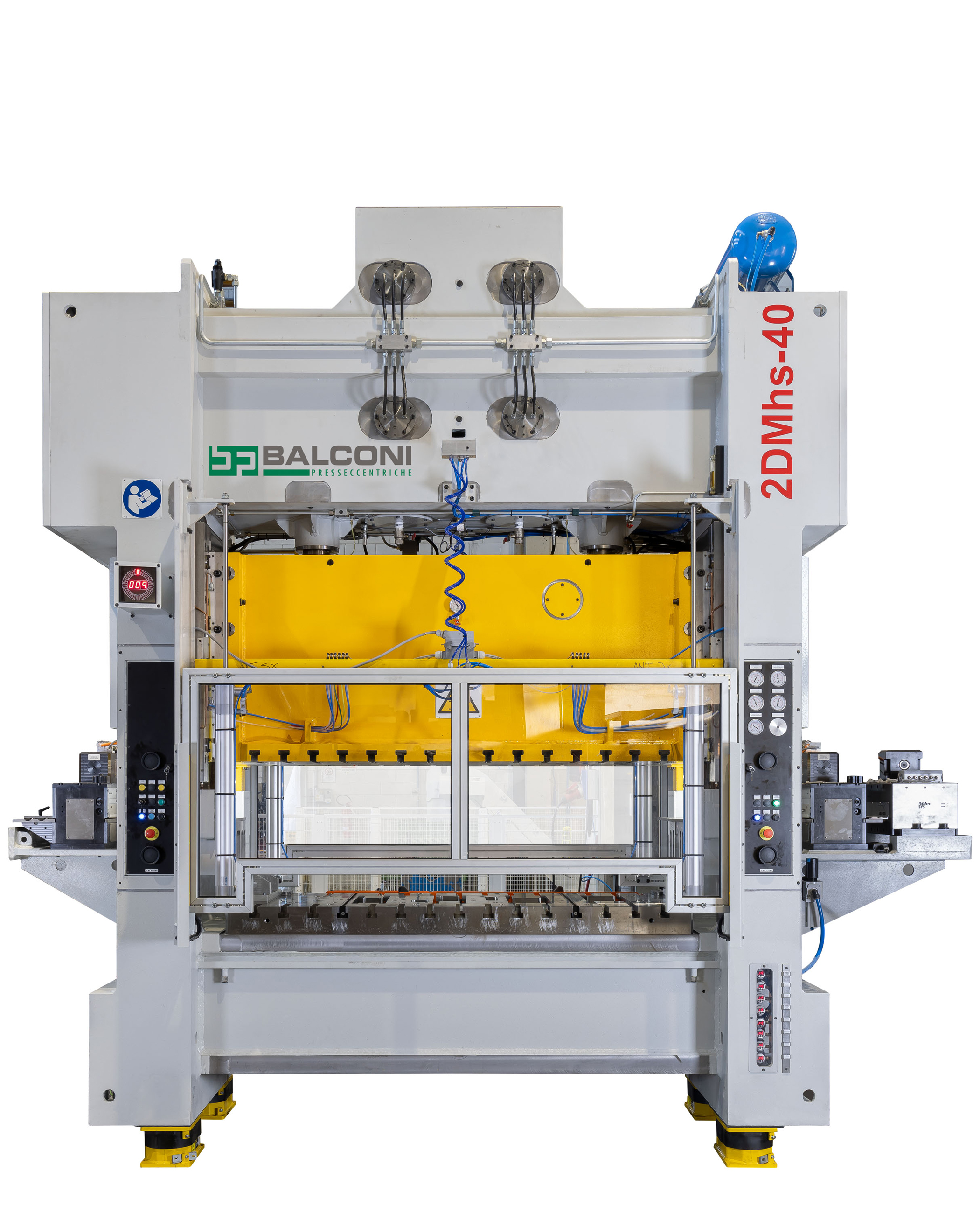

Blanking presses are machines intended for high speed production, usually stamping flat blanks or parts with small folds, and thin or average material thickness.

Balconi was the first Italian manufacturer of this type of presses, has acquired a long experience and has developed innovative technological solutions.

Balconi is still today one of the few European press manufacturers capable to offer and make high quality, technical and cost-effective solutions for high speed blanking.

Especially when using high tensile steel, during blanking a “breakthrough” phenomenon occurs generated by the instantaneous release of the elastic energy stored in the press frame.

In this situation the various parts of the press, such as the frame, the crankshaft, the connecting rods are subject to a high load that generates an increase of vibrations, tool wearing and damages to the machine if it is not properly designed, dimensioned, welded and manufactured.

Motors, electric and pneumatic components on the Balconi blanking presses are installed on shock absorbers to prevent possible untimely break-downs due to the high vibrations.

In our blanking presses, clearances are strictly checked during all the manufacturing phases. In fact excessive clearances may increase the effects of vibrations and of the “breakthrough” phenomenon.

The range of Balconi blanking presses is very wide and it includes machines up to 8.000 kN force.

HIGH SPEED BLANKING PRESSES FOR MOTOR LAMINATIONS

High speed blanking of motor laminations requires machines with special stiff frames, to stand the high vibration effects generated during production.

It is also necessary to have a high precision ram guiding, a conditioning system for the machine lubrication oil, a dynamic system to balance the inertia forces of the moving parts (crankshaft, connecting rods, ram and upper part of the tool) to allow the press to run at high speed without vibrations, installed on proper shock absorbers, without need of anchoring or foundations.

The press frame stiffness assures minimum bed deflections under total load to have a better press running, a longer tool life and a better accuracy of the lamination produced.

Quick lift system of ram: 100 mm to release the press and to inspect inside the tool area.

Presses for the production of motor laminations have very short stroke length and during tool set up the operator has a very small space to inspect the tool.

With the QUICK LIFT system, the operator can lift the ram by 100 mm from the operator panel. The ram lifts up automatically in a few seconds and at the end of the operation it goes back to the exact same working position, thus avoiding long and difficult adjustments of ram heights and assuring considerable time savings and higher precision.

Machine recirculating lubrication system with oil conditioning.

The lubrication of all working points is assured by a recirculating oil system with forced jet pressure and total recovery of the lubricant. The oil recirculates from the crown all around the press frame and its temperature is kept constant and under control by a thermo-chiller (to heat the oil when the temperature is cold and to cool it when it is hot). With such a system a better lubrication is assured and unequal frame dilations are avoided for a better and more accurate running.

The range of Balconi blanking presses for motor laminations is wide and it includes machines up to 6.300 kN force